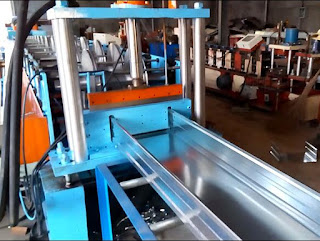

How to making cable tray roll forming machine? Roll forming machine for production process cable tray by chain driving, control by Siemens PLC system,LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run cable tray production line automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Forming parts length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication. Model,YX-009; Roll stations,12-30pcs; Speed,8-12m/min; Forming Machine size,16 *0.72*2.15m; Weight,5900kgs; Forming Power,7.5kw*2 pcs; Cable tray roll forming machine solution Cable tray machine photo for reference